X-Rays for Safety

Alloy wheel enthusiasts naturally appreciate the amazing look and great driving dynamics of these wheel rims. A topic of at least equal importance when it comes to alloy wheels, though, is safety. Only if the wheel’s engineering and production processes comply with all relevant safety standards can the consumer base their decision for one model or another purely on design aspects. A range of special inspection methods provides assurance that all wheels from quality manufacturers such as RIAL are technically faultless.

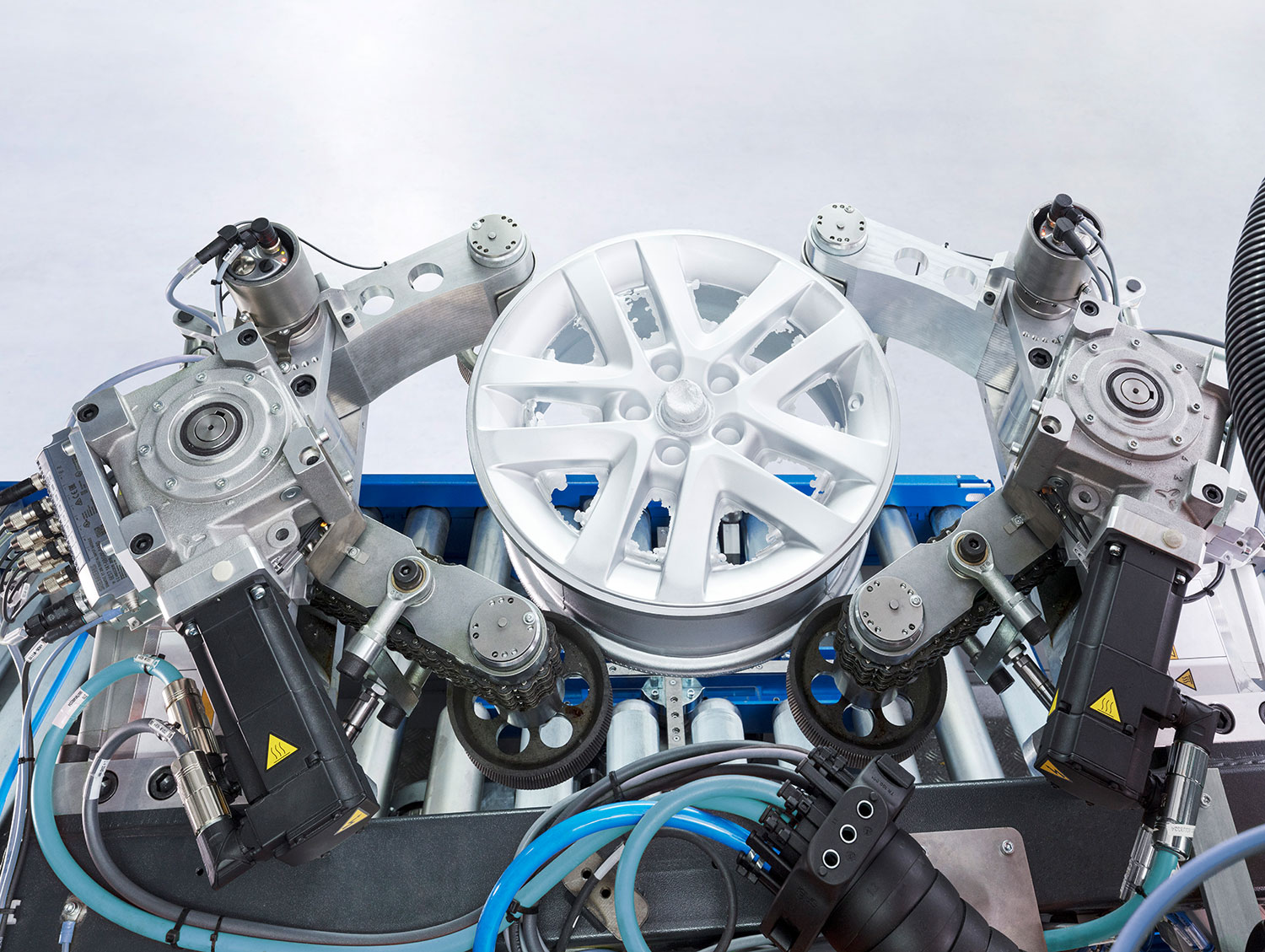

As in medical diagnostics, alloy wheel manufacturing requires taking a look at the inside. And just like doctors, wheel manufacturers rely on x-rays for this purpose. Each individual blank automatically undergoes an x-ray after casting before being processed further into a RIAL alloy wheel. In less than one minute, this x-ray inspection ensures 100% safety and is 100% nondestructive. Every wheel found to be error-free receives a label.

When the x-ray does find defects, the issue is usually blowholes. This metallurgy terms describes cavities that can form during the solidification of cast parts. With the right casting molds – technical term: gravity dies – and the proper working methods during casting, blowholes are quite rare. If the x-ray should reveal the presence of cavities, however, the affected blank is immediately recycled –safety comes first!